Mobile Equipment Sensors: Meeting the Challenges of Harsh Environments.

In today’s mobile equipment landscape, industrial encoders are essential components—from construction sites to agricultural fields—where automation drives efficiency and precision. Yet these environments present unique challenges for sensor technology. Dust, vibration, extreme temperatures, and moisture threaten the reliability of critical feedback systems, potentially causing costly downtime and compromised performance.

For mobile equipment manufacturers and operators, position feedback reliability isn’t just a technical specification—it’s essential for operational success. Whether controlling automated guided vehicles, positioning firefighting turrets, or monitoring crane hoist reels, these applications demand encoders that combine precision with environmental resilience.

For example, lets consider some typical challenges faced in mobile equipment applications:

A construction crane operating in driving rain needs consistent

feedback for safe load positioning.

Agricultural harvesters require precise timing control while enduring

constant vibration and dusty conditions.

Railway inspection systems must maintain accurate measurements

despite temperature fluctuations and mechanical shock.

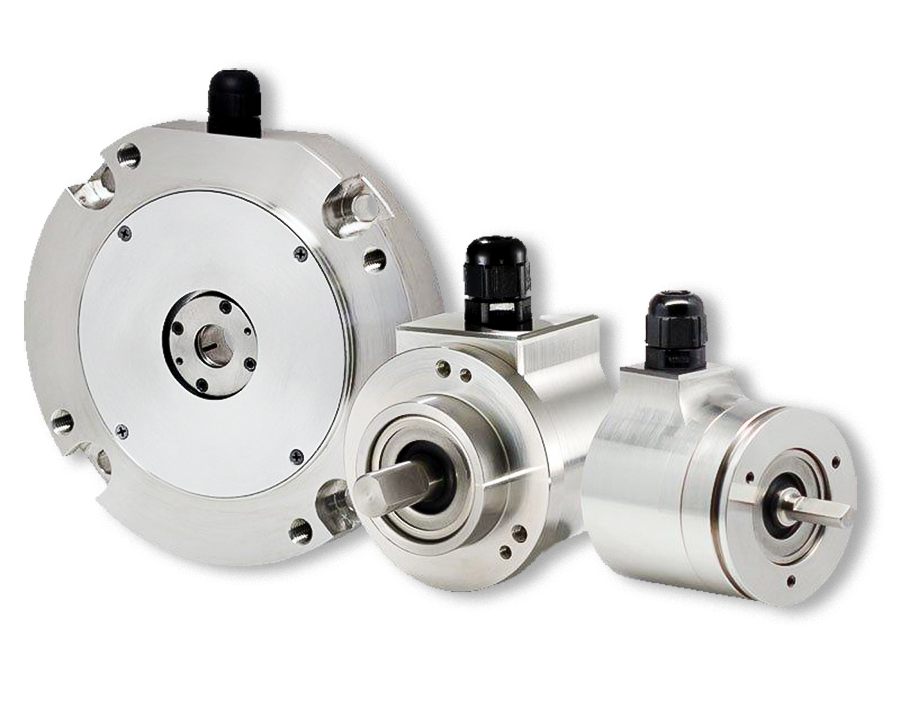

What sets industrial-grade encoders apart in these demanding environments is their robust design philosophy. The most effective solutions feature fully sealed housings with high ingress protection ratings (IP67 or above), ensuring dust and moisture resistance essential for outdoor operation. Shock and vibration resistance specifications should exceed industry standards, particularly for equipment experiencing constant movement over uneven terrain.

Temperature range capabilities are equally critical. Mobile equipment often operates in extremes, from sub-zero winter conditions to scorching summer heat. Industrial encoders designed with wide temperature ranges (-40°C to +85°C) ensure consistent performance regardless of ambient conditions.

Connection security represents another vital consideration. Mobile equipment experiences constant movement and vibration that can compromise traditional connections. Advanced industrial encoders feature robust connector options or sealed cable entries with strain relief to maintain signal integrity even during continuous operation.

For applications like motor feedback in automated guided vehicles, the encoder’s resolution and response time directly impact precision and efficiency. Similarly, encoders used in registration mark timing for firefighting turrets or harvesters must provide exceptional repeatability to ensure accurate positioning every time.

When evaluating encoder solutions for mobile equipment applications, look beyond basic specifications to consider the complete environmental profile of your specific use case. The ideal encoder balances precision performance with environmental resilience, ensuring reliable operation regardless of conditions.

By selecting encoders specifically engineered for mobile equipment challenges, manufacturers can ensure their systems maintain peak performance while minimizing maintenance requirements and maximizing equipment uptime—ultimately delivering better results in the field.

BEPC’s Model 960 encoder is designed to meet these challenges head-on. Its rugged, all-metal construction and innovative Opto-ASIC circuitry ensure reliability in the face of electrical noise, shock, and vibration. The Model 960’s low-profile design and versatile mounting options make it easy to integrate into a wide range of mobile equipment. By providing accurate absolute position feedback in a robust package, the Model 960 helps keep critical mobile equipment operating smoothly and efficiently.

Visit the British Encoder Products Company website for more information on Mobile Equipment Sensors: Meeting the Challenges of Harsh Environments.